If you work in manufacturing, you know that there’s rarely a quiet day on the job. In fact, aside from the spike of COVID-19 in 2020, hearing loss has historically been the most recorded occupational illness in manufacturing.

In 2019, the Bureau of Labor Statistics estimated that potentially damaging noise levels put 18 million workers at risk, and led to approximately 14,500 work-related hearing loss cases. Furthermore, the estimated workers’ compensation payout from employers with employees who experience hearing loss is around $242 million.

So, as an employer, what should you do to protect both your team and your company? Let’s break it down.

OSHA’s Rule on Hearing Safety

According to OSHA’s Regulation 29CFR 1910.95, employees exposed to sound levels at, or above, 85 decibels adjusted (dBA) for an 8-hour time-weight average must be provided with some means to mitigate their exposure to the hazard.

In other words, if an employee endures hazardous noise for a specific period of time, his/her employer must monitor that employee’s hearing and offer ways to conserve and protect it.

Also, starting on May 17, 2022, OSHA will also begin enforcing a Regional Emphasis Program for Noise-Induced Hearing Loss. This program will target manufacturing industries with high rates of occupational hearing loss in Colorado, Montana, North Dakota, and South Dakota.

“This regional emphasis program will help ensure manufacturing employers in Colorado, Montana, North Dakota and South Dakota do what is necessary to protect their workers from exposures to excessive noise and prevent permanent hearing loss,” said OSHA Regional Administrator Jennifer Rous in Denver.

“OSHA hopes the emphasis program will remind manufacturing industry employers to follow required safety standards and alert workers to the related hazards and reduce workplace injuries,” Rous added.

The Effects of Hearing Damage

Perhaps the most common effect of hearing damage is Tinnitus.

Most people experience the sensation of ringing in their ears at some point, but those suffering from Tinnitus may hear this ringing or booming sound constantly.

NIOSH reports that 8 percent of all workers suffer from Tinnitus, which unfortunately may be the first noticeable sign of damage.

Workers whose hearing is affected by ototoxic chemicals in combination with high noise levels are at the highest risk for hearing damage. Ototoxic exposure can occur during jobs such as painting, radiator repair, weapons firing, boat building, and more.

Loud noise on the worksite can also physically and mentally affect employees.

OSHA notes that “loud noise can create physical and psychological stress, reduce productivity, interfere with communication and concentration, and contribute to workplace accidents and injuries by making it difficult to hear warning signals.”

Hearing loss may not physically hurt, but it can deeply impact the ability to communicate with others, leading to social and psychological distress.

It can also lead to loss of sleep and fatigue.

How to Get Ahead of Hearing Damage

There are several ways to control and reduce worker exposure to noise in workplaces where sound exposure is excessive.

You can do that with:

- Engineering controls: These controls involve modifying or replacing equipment or making related physical changes at the noise source or along the transmission path to reduce the noise level at the worker’s ear. Effective engineering controls include

- Choosing low-noise tools and machinery

- Maintaining and lubricating machinery and equipment (e.g., oil bearings)

- Placing a barrier between the noise source and employee (e.g., sound walls or curtains)

- Enclosing or isolating the noise source.

- Administrative controls: These are changes in the workplace or schedule that eliminate or reduce worker exposure to noise. Examples include:

- Operating noisy machines during shifts when fewer people are exposed

- Limiting the amount of time a person spends at a noise source

- Providing quiet areas where workers can gain relief from hazardous noise sources

- Controling noise exposure through distance is often an effective, yet simple and inexpensive administrative control. Specifically, for every doubling of the distance between the source of noise and the worker, the noise is decreased by 6 dBA.

- Audiometric testing: This is a great way to test and see if employees are suffering from any loss of hearing. Audiometric testing can prevent further, more severe hearing loss and hefty fines from OSHA.

For audiometric testing, which is required by OSHA, Worksite Medical brings the examinations directly to your worksite.

You can get up to six audio booths and up to 20 exams per hour for efficient testing. Audiometric testing is pure tone air-conducted hearing testing performed in each ear at frequencies of 500, 1K, 2K, 3K, 4K, 6K, and 8K.

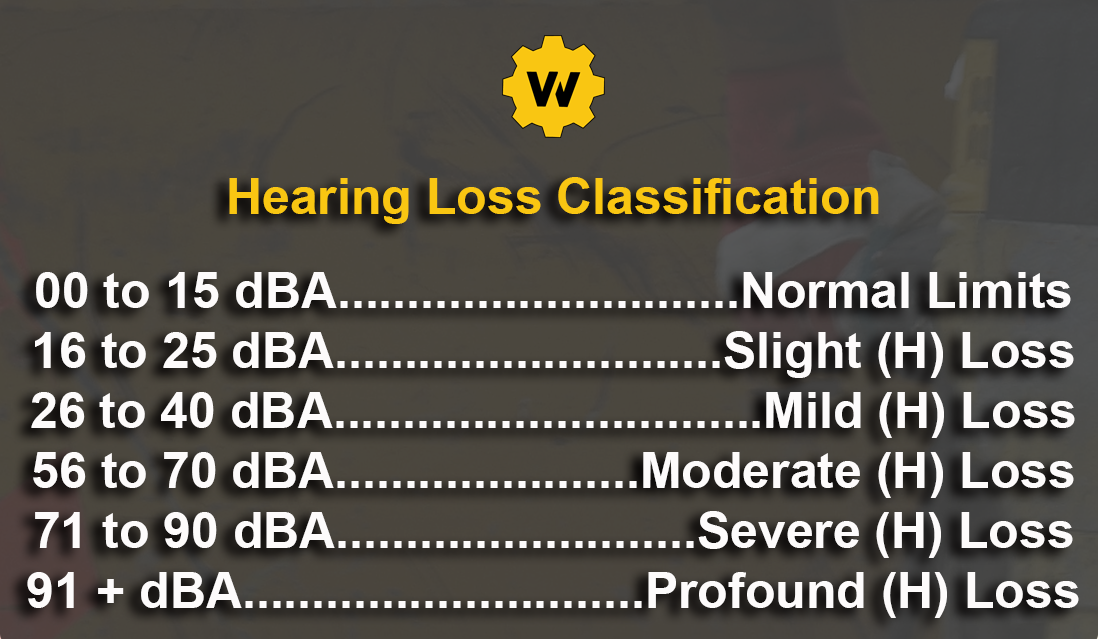

This sort of testing identifies hearing levels and a sensitivity to the exposed sound.

We also provide hearing safety training. And, you never have to send your team members away to a clinic.

Get your risk-free quote or schedule your on-site audiometric exams below. Let’s keep your team safe and stay ahead of OSHA inspections together.

Take a virtual tour of our mobile medical units HERE.

***

About Worksite Medical

In most cases, OSHA requires medical surveillance testing, and at no cost to employees.

Worksite Medical makes that program easier with mobile medical testing.

We conduct on-site respirator fit tests, as well as audiometric exams, pulmonary function tests and heavy metal lab work, right on your job site. We also keep accurate, easy-to-access medical records for your convenience. You’ll keep your employees at work, and stay ahead of OSHA inspections.

With Worksite Medical, a mobile medical testing unit — we can bring all the resources of a lab to you. Our certified lab technicians can perform both qualitative and quantitative respirator tests to ensure a perfect fit.

Protect your team and your workplace now with Worksite Medical. Not sure what you need? Try our medical testing wizard here.

Give us a call at 1-844-622-8633, or complete the form below to schedule an on-site visit or to get your free quote!