After multiple inspections and a failure to abate hazards, OSHA cited a Milwaukee metal fabricating facility for failing to implement a hearing conservation program and for exposing workers to dangerous machines.

During two different 2020 inspections, OSHA identified dangerous machine and noise hazards at the facility. Inspectors returned to the facility in January 2021, issuing citations for four repeated, nine serious, and three other-than-serious safety violations, after the company failed to provide information on how it abated the dangerous working environment.

Most notably, the employer did not administer a continuing, effective hearing conservation program, which includes a noise monitoring program, an audiometric testing program, and a noise training program

“Ignoring hazards identified in earlier OSHA inspections suggests that [the company] is not committed to protecting its workers’ safety and health,” said OSHA Area Director Chris Zortman in Milwaukee.

“Amputation and hearing loss are irreversible life-altering injuries. Companies must implement required safety and health measures to prevent employee exposure to these hazards.”

In all, the company faced proposed penalties of $216,307. They have 15 business days from receipt of its citations and penalties to comply, request an informal conference with OSHA’s area director, or contest the findings before the independent Occupational Safety and Health Review Commission.

Regional Emphasis Program

The citation occurred on the heels of the regional emphasis program implementation.

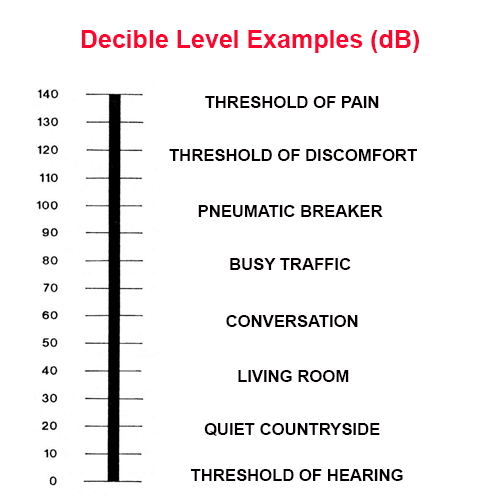

Last month, OSHA launched the program, which focuses its enforcement efforts on reducing occupational noise exposure and promoting hearing conservation programs. Employers are required by law to implement a hearing conservation program when the average noise exposure over eight working hours reaches or exceeds 85 decibels.

For reference, this noise level compares to the sound of city traffic (from inside a vehicle) or a gas-powered leaf blower.

Establish a Hearing Conservation Program in 6 Steps

Stay ahead of the noise by establishing a hearing conservation program with the following steps:

- Monitor the noise on your worksite. Your program should be based on how much noise your worksite creates. The traditional method is to use a decibel meter to measure the average noise exposure over time. Another way is to focus on the noise generated by specific tasks such as using a jackhammer. NIOSH offers a helpful power tool resource with sound information for common tools. The CDC also created the SLM workplace noise app for iPhone to help monitor noise levels.

- Reduce and control noise. Administrative controls can be used to limit the time employees spend around noisy equipment. Employers should also consider noise levels when choosing equipment. It may be worth it to spend more on tools with reduced noise.

- Provide hearing protection. Everyone’s ears are different, so employers should provide a range of PPE such as earmuffs and plugs so employees can find what works best for them.

- Schedule audiometric testing. Workers should be tested at least once a year to see if they are experiencing any hearing loss. Save time and productivity by using convenient on-site testing from Worksite Medical.

- Evaluate your program. Audiometric testing will reveal whether or not a worker is still suffering from hearing loss. If so, employers need to take even more steps in hearing conservation.

- Provide training and education. Employees might not realize the importance of wearing proper PPE, so it’s important to set time aside to help workers understand how and why they need to protect their hearing.

Download your free hearing conservation program fact sheet here.

Bringing It All Together

When it comes to a written hearing conservation program, and all other things health & safety related, OSHA takes matters very seriously.

Don’t become another stat on the administration’s website. Go mobile instead! With onsite occupational health testing by Worksite Medical, all of your OSHA-required medical surveillance exams right to your job site.

We conduct on-site respirator fit tests, as well as audiometric exams, pulmonary function tests and heavy metal lab work, right on your job site. We also keep accurate, easy-to-access medical records for your convenience. You’ll keep your employees at work, and stay ahead of OSHA inspections.

Protect your team and your workplace now with Worksite Medical. Not sure what you need? Try our medical testing wizard here.

Give us a call at 1-844-622-8633, or complete the form below to schedule an on-site visit or to get your free quote!