Beryllium is a vital material in aerospace, defense, and various industries. But, though the metal remains an important part of manufacturing, beryllium exposure poses severe risks if not managed appropriately. In fact, in some cases, it can even prove fatal.

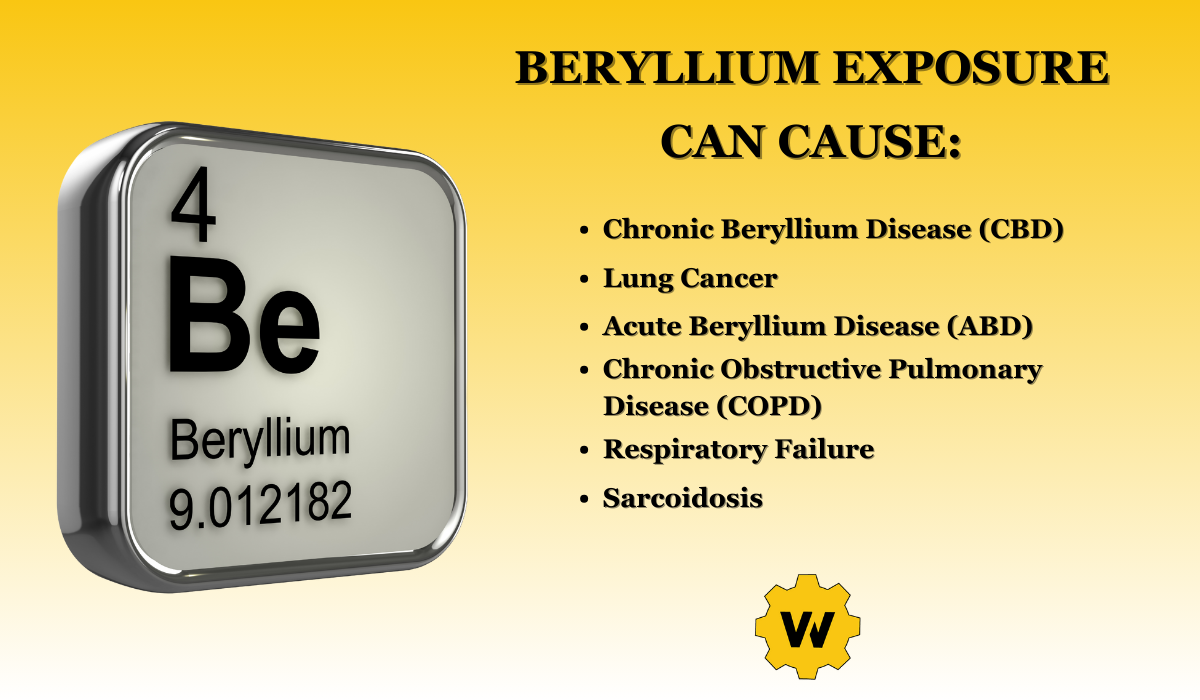

A known carcinogen, beryllium can affect a number of tissues and organs. Most notably, breathing in fumes or dusts can cause significant – even fatal – respiratory disease, such as chronic beryllium disease. It can also damage the liver, kidneys, heart, and nervous system.

Now, a recent OSHA inspection reveals one Massachusetts alloys manufacturer fell far short in protecting their employees from the dangers of the metal.

Inspectors discovered that employees at the facility were overexposed to airborne concentrations of this toxic substance within the foundry and grinding room, while engaged in handheld grinding and parts fabrication operations on beryllium aerospace components.

So, why does OSHA take beryllium exposure so seriously? What steps can you take to mitigate the dangers?

Here, we’ll examine OSHA’s findings, and break down the critical importance of respiratory health in the workplace.

Let’s break it down.

Related Article: Here’s the Breakdown of OSHA’s New Beryllium Guidance

Related Article: Sarcoidosis Linked to Silica, Beryllium Exposure

Addressing the Violations Issued

OSHA’s inspection unveiled several critical violations requiring immediate attention. Most notably, the Massachusetts-based company was found to have failed in the following key areas:

1. Timely Beryllium Exposure Monitoring

Follow-up monitoring of beryllium exposure, a crucial step in safeguarding employees’ respiratory health, was not conducted in a timely manner.

2. Exposure Control Plan and Engineering Controls

The company not only lacked adequate engineering controls, but also failed to implement an effective exposure-control plan. These measures are pivotal in reducing and minimizing employees’ exposure to beryllium.

3. Proper Handling of Contaminated Clothing

Beryllium dust, like many toxic materials, can cling to clothing and follow workers home – where it might then affect friends and family, including young children. Allowing the storage of beryllium-contaminated clothing in personal lockers alongside employees’ street clothes poses a significant risk of cross-contamination.

4. Laundering of Protective Coveralls

As mentioned above, toxic dusts often sticks to clothing. Ensuring that reused and laundered protective coveralls are entirely free of beryllium contamination is essential for effective protection.

5. Adequate Change Room Facilities

Employees required to change into personal protective equipment were not provided with an adequate change room, potentially compromising their respiratory health.

6. Workbench Surface Contamination

Maintaining workbench surfaces free of beryllium to the greatest extent feasible is crucial for preventing unintended exposure.

7. Proper Disposal of Contaminated Items

Rags, gloves, paper towels, and other beryllium-contaminated items were not disposed of in a manner that minimizes the risk of further exposure.

8. Adequate Warning Signage

The presence of adequate warning signage is imperative to alert employees to potential hazards and ensure heightened vigilance. To that end, OSHA generally requires warning signs in a wide variety of dangerous locations.

OSHA’s Penalties

OSHA issued citations to the company for 11 serious violations, and one other-than-serious violation, reflecting the gravity of the hazardous conditions identified. In all, proposed penalties totaled $69,251.

The company now has 15 business days from receipt of citations to comply, request an informal conference with OSHA’s area director, or contest the findings before the independent Occupational Safety and Health Review Commission.

Protecting Your Team from Beryllium Exposure

If your team works with or around beryllium, you’ll want to take a number of proactive steps to protect from exposure. To start, consider the following.

Personal Protective Equipment (PPE):

- Wear appropriate PPE, including respiratory protection, such as or respirators with high-efficiency particulate air (HEPA) filters designed for beryllium exposure.

- Utilize protective coveralls, gloves, and eye protection to prevent skin contact and inhalation of beryllium particles.

- See OSHA’s Guidelines on Personal Protective Clothing and Equipment (PPE) – Paragraph (h) of the Standard

Engineering Controls:

- Implement local exhaust ventilation systems to capture and remove airborne beryllium particles at the source, minimizing inhalation risks.

- Ensure adequate ventilation in work areas to maintain a safe and well-circulated environment.

Work Area Management:

- Keep work surfaces and equipment as free of beryllium dust and residue as possible through regular cleaning and maintenance.

- Establish designated areas for specific tasks involving beryllium to contain potential contamination.

- See OSHA’s Guidelines on Beryllium work areas and regulated areas – Paragraph (e) of the standard

- See OSHA’s Guidelines on Housekeeping – Paragraph (j) of the Standard

Proper Handling and Storage:

- Handle beryllium-containing materials with care, minimizing the generation of dust or aerosols.

- Store beryllium-contaminated clothing and equipment separately from personal items to prevent cross-contamination.

- See Occupational Safety and Health Standards- Toxic and Hazardous Substances 1024 [Beryllium]

Personal Hygiene:

- Encourage frequent hand-washing with soap and water to remove any potential beryllium particles from skin.

- Avoid eating, drinking, or smoking in areas where beryllium exposure is possible.

- See OSHA’s Guidelines on Hygiene Areas and Practices – Paragraph (i) of the Standard

Training and Education:

- Provide comprehensive training to workers on the hazards of beryllium, safe work practices, and proper use of PPE.

- Ensure workers understand the importance of early reporting of any potential exposures or symptoms.

- See OSHA’s General Resources on Beryllium

Regular Monitoring and Testing:

- Conduct periodic air monitoring and exposure assessments to gauge beryllium levels in the work environment.

- Perform medical surveillance, including regular health assessments and lung function tests, for early detection of any respiratory issues.

- See OSHA’s Article on Beryllium Medical Surveillance Information for Workers

Emergency Response Plans:

- Establish clear protocols for responding to spills, leaks, or accidents involving beryllium, ensuring swift containment and cleanup.

- See OSHA’s Guidelines on Emergency Preparedness and Response

Maintain Proper Ventilation and Filtration:

- Ensure that ventilation systems are well-maintained and functioning optimally to effectively capture and remove airborne beryllium particles.

- Regularly inspect and replace filters in ventilation systems to guarantee their efficiency.

Follow Regulatory Guidelines:

- Adhere to OSHA and other regulatory standards governing beryllium exposure in the workplace, and stay updated on any changes or revisions.

- See OSHA’s Guidelines on Occupational Exposure to Beryllium; Final Rule

- See OSHA’s Updated Interim Enforcement Guidance for the Beryllium Standards

Seek Medical Attention Promptly:

- If a worker suspects any potential exposure to beryllium, they should seek immediate medical attention and inform their healthcare provider of the situation.

- See OSHA’s Article on Health Effects of Beryllium

By diligently following these protective measures, you can significantly reduce the risk of beryllium exposure and safeguard your team’s respiratory health in the workplace.

Stay Safe, Stay Compliant

Keeping your team safe from hazards like beryllium exposure is not only the right thing to do; in fact, it’s the law. OSHA’s standards constitute legal requirements, designed to keep tens of millions of workers safe across the nation.

And, as the recent investigation at the Massachusetts plant shows, OSHA takes enforcement seriously.

Fortunately, if you need help keeping your team safe & your company compliant, there’s an easy, no-stress solution.

At Worksite Medical, we make it easy to get the medical surveillance your team needs to stay safe and compliant. Instead of sending your team away to an off-site clinic, we bring everything right to your jobsite. Respirator fittings, hearing testing, heavy-metal testing, x-rays, physical exams, and much, much more, brought right to you.

Minimize your downtime, minimize your stress, and maximize your efficiencies.

About Worksite Medical

In most cases, OSHA requires medical surveillance testing, and at no cost to employees.

Worksite Medical makes that program easier with mobile medical testing.

We conduct on-site respirator fit tests, as well as audiometric exams, pulmonary function tests and heavy metal lab work, right on your job site. We also keep accurate, easy-to-access medical records for your convenience. You’ll keep your employees at work, and stay ahead of OSHA inspections.